SAICA Group manufacturing facility, Livingston

Article in NSC July/August 2021

Steel frame repackaged

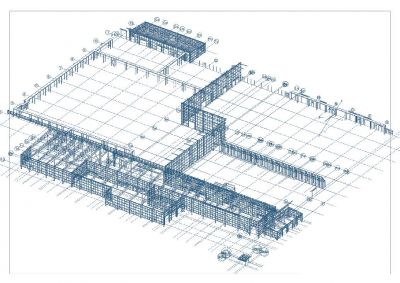

A steel-framed distribution centre in Livingston is being extended and converted into a new manufacturing facility for Spanish-based SAICA Group.

Packaging manufacturer SAICA Group is constructing a new state-of-the-art facility in Livingston, West Lothian by converting an existing distribution centre and extending the structure with new steel-framed extensions. SAICA says the investment demonstrates its commitment to the Scottish market for the long-term, and the new site will offer the latest technologies to create sustainable packaging solutions. Changes in customer demand, aging facilities and challenges associated with existing site locations led the company to take a major step in order to increase its capacity and offering for its customers. The leading Scottish packaging business will be transitioning from a two-site structure with the decommissioning of its Edinburgh and Milngavie sites, to one main plant in Livingston.

“Once fully operational, our new Livingston site will offer the latest and most innovative technologies while improving our service and capacity,” says Adam Haycock, Regional Director for SAICA Pack Scotland. “This new site gives us the capacity to invest further in the future as we want to remain a leading provider of corrugated packaging in Scotland and enhance our offering to our customers.”

Robertson Construction is leading the £18M project, which started on site during November 2020, once an internal strip-out programme had been completed. The existing structure measures approximately 205m-long × 120m-wide and was previously a Lidl distribution centre, built more than 25 years ago. More recently, the steel-framed structure has had a couple of extensions added, that has created today’s overall building. The existing structure’s steel frame is said to be ideal for its new purpose as it is a large braced open-plan building. A series of roof trusses, up to 36m-long, provide the structure with long uninterrupted spans. There is also an attached office block that runs along the entire eastern elevation (120m), which has one and two-storey zones. The 12m-wide office is being refurbished as SAICA’s new admin hub.

“The internal steelwork is mostly galvanized and in good condition and only needs to be repainted in some locations, such as the later extensions which were built using non-galvanized members,” explains Robertson Construction Senior Project Manager Paul Epton.

The largest of the three new steel-framed extensions runs along the northern elevation. Like all of the new steelwork, it is a standalone braced structure, separated from the existing building by a movement joint. It is 160m-long and reaches a maximum width of 37m, with two other areas having widths of 31m and 17m. “The extensions have internal columns, positioned away from the existing building. This 1.5m to 2.5m distance was deemed to be sufficient to prevent any clash between new and old pad foundations,” explains IDOM Structural Engineer Michael Dyer. The widest part of the extension, which is 37m-long, has internal columns creating two spans. The other two parts are column-free, with a series of 28m-long trusses that have a maximum depth of 3.5m, spanning one zone, and a series of rafters spanning the 17m-long area.

Occupying the remaining 50m of the northern elevation and abutting the extension is an automated warehouse. This steel-framed structure is not part of the main steel package, which is being undertaken by Hescott Engineering, as a contractor that specialises in supplying and installing automated warehouses has been employed. Feeding the automated area, a large corrugator machine will be installed within the northern extension. In order to create sufficient space for the installation of the necessary conveyors for this machine, three columns from the existing structure have been removed. Straddling these areas, RHS beams have been installed at roof level, that carry the loads to adjacent columns.

“The extensions follow the same column grid pattern as the existing structure in most areas,” says Mr Dyer. “However, the installation of new machinery takes precedence and in the northern elevation the grids are slightly different and so removing three columns was the solution.” The south elevation and the west elevation extensions are both single span braced steel structures, with no internal columns. The former is 42m-long × 16m-wide, and the latter is 25m-long × 9m-wide. Once the new steel frames are complete, similar cladding to the existing structure is due to be installed, creating a seamless envelope connection between new and old, and thereby forming the desired larger facility for SAICA.

Inside the existing building, new steelwork has been erected to form a partition wall, that divides the structure roughly in half and consists of full height columns with CFS cladding rails. The columns are connected to the existing trusses via deflection heads. New steelwork also forms 5.5m-high walkways in various areas of the existing building. The walkways are stabilised by a combination of steel portal frames and braced frames.

David Cairns, Managing Director, Robertson Central East, said: “This is a significant project for SAICA as they bring their Scottish operations together and we are delighted to have been appointed as the construction partner who will bring their vision for the site to life. We will be continuing to work closely together through the construction period to ensure the successful delivery of this strategically-important facility.”

Construction is due to complete in December 2021, with SAICA intending to open the new site directly after completion.

| Architect | IDOM |

| Structural Engineer | IDOM |

| Steelwork Contractor | Hescott Engineering |

| Main Contractor | Robertson Construction |

| Main Client | SAICA Group |