West Calder High School, West Lothian

Article in NSC June 2017

School goes for steel option

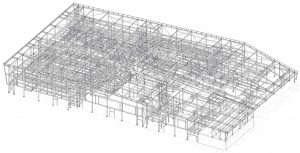

Set to replace an existing school in a nearby village, the West Calder High School has opted for a steel framing solution for cost and efficiency.

By Martin Cooper

Work is progressing on a new 1,100 capacity secondary school in the West Lothian village of West Calder. The project will replace a nearby existing school and includes a host of amenities such as a swimming pool and other indoor and outdoor sports facilities. The school is West Lothian Council’s largest ever single investment in education. It is being developed through Hub South East Scotland, with Morrison Construction appointed to build the new school.

Due to open in 2018, the project architects say the school has been designed with the pupil experience at the core, as well as providing facilities accessible to the local community. The swimming pool, fitness suite, games hall and outdoor sports pitches will be open to the public at certain times, as will the amphitheatre, which is a feature that forms an integral part of the school’s overall design.

The multi-use amphitheatre is positioned in the centre of the school with the classrooms located around the perimeter, while more flexible learning space is located in nearby main circulation areas. As well as the amphitheatre, most of the school’s facilities, such as the pool, games hall and dining area, are all located within large column-free spaces. Consequently, their buildability was one of the main reasons for choosing a steel framing solution for the project. “Early in the design process we looked at all framing options, weighing up their pros and cons. Ultimately to build the required long spans efficiently and quickly we went with a steel-framed solution,” says Arup Lead Project Engineer Ian Miller.

However, before any of the structure could be built, access to the project’s site had to be improved. During the early stages of the job’s 91-week programme, a narrow local road, passing a number of private properties was used. Construction of a new £5.5M bridge over the A71 and a link road has now provided the site with a haul route for materials. Preliminary works also included Morrison undertaking ten weeks of grouting up of old mine workings that run beneath the site.

Once the bridge was in place, Hescott Engineering was able to begin its steel erection in February. A cut and fill operation, to form a level base for the school building on this sloping site, was also under way at this time. Approximately 25,000m3 of overburden has been excavated from the site, with almost 13,000m3 of this spoil re-used. Sitting on concrete pad foundations, the steelwork erection programme has followed on behind the groundworks and earthmoving teams, with all of these trades working in a southerly direction from the lowest end of the site.

In order to integrate the school to the sloping topography, two retaining walls have been constructed across the building’s footprint, approximately dividing the building into thirds. The walls form two steps, 3m and 5m-high respectively. Consequently, the 100m-long × 60m-wide building descends from three-storeys down to one storey at the southern end.

Most of the classrooms, as well as the school’s main entrance, are located within the three-storey northern end of the building. Because of their different uses, many of the classrooms are of varying sizes. This has resulted in an irregular structural grid and the need for numerous transfer beams to support the irregularly spaced columns. Overall the school building has a composite design with steelwork supporting metal decking with a concrete topping. Bracing, located in the roof and in stairwells, provides the frame with its stability.

Dominating the central area of the school, the amphitheatre and its adjacent feature staircase are the most complex part of the project’s steelwork. As well offering access to all of the school’s floors, the staircase is 20m-wide and incorporates terraced seating. A series of facetted rakers forms the curved shape of the terrace as it wraps around a portion of the performance space. Supporting the staircase is a series of girders each weighing in excess of 4t.

As well as erecting the steelwork and installing the metal decking, Hescott Engineering also lifted in the precast terracing units. According to Hescott’s Business Development Manager John Dowds, a total of 37 crane lifts were needed to install the precast units.

Terraced seating for the amphitheatre

A number of varying floor levels have resulted in a complex steel design

Three 20m-long × 3.5m-deep trusses form the amphitheatre’s open-plan column-free space. One of these trusses is positioned at the north end of the space, where the building steps up from two storeys to three. The other two trusses tie into the first truss and span southwards creating the open void.

Looking at the school from the outside the most striking feature will be the roof. Intended to be a nod to the surrounding countryside, the roof slopes down from the three-storey element towards the single storey area, incorporating three different pitches.

A West Lothian Council spokesperson said: “The modern, high-quality school will be a fantastic resource for local young people, providing an ideal learning environment for them to achieve their full potential. This investment will help ensure that West Lothian continues to have one of the best school estates in Scotland.

| Architect | Archial NORR |

| Structural Engineer | Arup |

| Steelwork Contractor | Hescott Engineering |

| Main Contractor | Morrison Construction |

| Main Client | Hub South East Scotland on behalf of West Lothian Council |