Wimbledon No.1 Court

Structural Steel Design Awards 2019 - Award

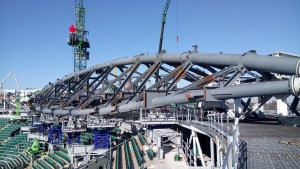

Constructed over a three-year period, the steelwork element of the re-development of the No.1 Court included the demolition of the existing roof built in 1997, infilling and extension of the level 4 and 5 floorplate steel and new fixed roof, followed by the construction of a moving roof that will provide full rain cover during the Championships.

The main client requirement was that the works to the No.1 Court would still allow the Championships to take place with a minimum of disruption. This resulted in one of the more interesting aspects of the build and necessitated the development of a staged site programme that incorporated into the working methods and temporary works the appearance and character expected of the All England Lawn Tennis Club.

Other objectives for the design were to extend the terraces to maximise the seating within the existing structure and provide new, enlarged and improved debenture/hospitality facilities, whilst optimising grass growing conditions throughout the year both on the No.1 Court itself and the adjacent grass courts. In addition, the movable roof had to be deployed, and the internal environment conditioned, both to eliminate condensation on the playing surface and provide a comfortable spectator environment, all within a 30-minute stoppage of play.

The structure for the east and west sections of the static roof is largely symmetrical. There are long span prismatic trusses spanning 47m between the existing cores, and 80m between new supporting columns installed in the corners. The exception is the NW corner, where the truss is supported on another transfer truss spanning between the cores. The top and bottom chords follow the profile of the cladding surfaces and are large tubular sections. These main elements provide sufficient vertical stiffness to support the weight of the static and moving roofs, good lateral stiffness to resist the lateral forces imposed on the structure from both wind and the moving roof, and create a large open internal space within the truss that facilitates the integration of the MEP equipment.

A secondary structure provides support to the rails that carry the moving roof. The inclination of the prismatic trusses, and the positioning of this secondary structure, enables the load from the moving roof to be located over the bottom chord of the prismatic truss for structural efficiency.

The southern roof utilises two planar trusses spanning across the width of the bowl. The inner truss spans between a planar truss in the corners which transfers the load back to the new corner columns and the existing cores. The rear truss is located such that it is spanning between the cores. This arrangement allows the inner roof structure to cantilever out over the bowl, with the forces being resolved as a push-pull on the two trusses.

The north quadrant of the static roof differs from the south as it carries a large quantity of plant. To achieve the necessary structural strength, the last moving roof truss, that is actually always static, has been incorporated into the static roof structure. This truss is much deeper than the southern roof trusses, and therefore offers a more efficient structural form.

The retractable roof for No. 1 Court is a concertina system using fabric panels tensioned between long span triangular trusses, which in turn span between the east and west sections of the static roof. The triangular trusses, approximately 6.6m-deep and 1.5m-wide, span in an east-west direction over the court, and are supported on bogeys that run on rails supported by the east and west primary prismatic trusses. Bearings on the bogeys at each end allow thermal expansion and contraction in the plane of the truss and the leading trusses of the two halves have bearings on the east side that are fixed in the east/west direction to provide some stability to the group.

The complex geometry and heavy loading led to the development of jigs that were used in the workshop to achieve the requisite accuracy of fabrication of highly complex connection assemblies, some of which included up to twelve incoming members to a single node.

On site, not only were the existing cores used for permanent support of the fixed roof steelwork, they were also used as temporary support for the four tower cranes used during construction, for which they were temporarily post-tensioned.

The use of structural steelwork, with offsite fabrication and rapid site assembly, allowed the site construction to take place in the windows between Championships. Further, the spans required for the roof trusses and the stiffness needed to control the movements at the critical interfaces between the fixed and moving parts, precluded any form of construction other than steel.

Overall, the structure has been designed to be in keeping with the existing structure, whilst including up-to-date technology. This has allowed the architectural aspects of the existing site to be maintained.

| Architect | KSS |

| Structural Engineer | Thornton Tomasetti Ltd |

| Steelwork Contractor | Severfield |

| Main Contractor | Sir Robert McAlpine |

| Client | The All England Lawn Tennis Club |

Judges' comment

Installing a moving roof over No.1 Court involved the adaption of the 1997 building without interrupting the annual tennis Championships. This extraordinarily complex work was carried out over three seasons with minimum public awareness. Large movable steel trusses installed to very exacting tolerances over the existing building provide a roof that can shelter a match from rain within minutes.