Lots Road Chelsea Waterfront, East Tower

Article in NSC March 2021

Crowning glory

A signature steel roof, known as the halo, creates an architectural highlight of a 25-storey London residential tower.

Forming part of the Lots Road Chelsea Waterfront development in West London, structural steelwork is playing an important role in the topping out of the scheme’s 25-storey residential East Tower. The prestigious scheme, which has been master planned by renowned architect Sir Terry Farrell, will include two residential towers, East and West (the latter being 37-storeys), three riverside buildings arranged around landscaped gardens and the redevelopment of the historic Lots Road Power Station.

“Lots Road Chelsea Waterfront is a 420-unit development comprising both high-end residential and affordable accommodation with 260 units contained within the existing power station. This project has taken a disused and aged building and turned it once again into the focal point of the local community,” explains JRL Group Project Director Donal Reale. Overlooking the River Thames, the development will also include shops, restaurants and bars together with a residents’ health and fitness club.

“As part of this development we are constructing the East Tower, which is a 25-storey apartment block comprising 40 high-end residential properties and capped off at level 25 by an impressive steel roof structure,” adds Mr Reale. “This steel structure has defined the complex shape and finish of the tower and could not have been formed by standard concrete construction. Appropriately named the halo as it forms a fully lit ring in its permanent position. This oval shaped building will be a stand-out structure for the local community.”

Both of the residential towers are topped with similar sloping steel roof structures; architectural features that also accommodate the uppermost penthouses, maintenance access and BMU support areas. The West Tower was completed in 2019 by a different contractor, but the project team say they learnt a lot from visiting this project during its construction and discussing its steelwork design. This has ultimately enabled the East Tower’s roof, which tops out 12-storeys lower than its neighbour, to be erected quickly and effectively.

J Reddington Engineering Manager Mark Urbinati explains: “As both buildings have a similar steel roof, we were able to use the lessons learnt from the West Tower when it came to this tower. This especially helped us, when it came to working out the best erection sequence and making sure all of the temporary works were in place. Erecting steelwork on both towers was challenging because of the height and that’s why steel was chosen for the roof structures. Steelwork is lighter than other materials and can be prefabricated into erectable elements, cutting down on the number of crane lifts and limiting the amount of work at height.”

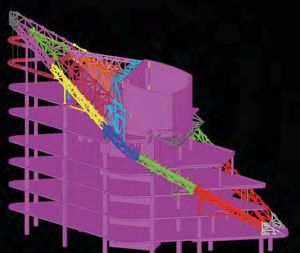

Starting at level 20, the East Tower’s steel halo roof is bolted to the top of the in-situ concrete superstructure and, following the building’s stepped design for its upper floors, it slopes upwards to form a peak that is approximately 7m above the tower’s level 25. It is formed by a series 24 perimeter trusses that straddle either side of the tower’s central core. Towards the top of the halo, infill steelwork connects the trusses and provides some extra stability, while also forming the roof to the uppermost floor. The trusses are typically 2m-wide x 1.05m-deep and vary in length from the longest at 11.5m to the shortest at only 1.5m-long.

Prior to the steelwork programme beginning on site, temporary works had to be installed to ensure a safe working environment for the erectors. A series of screens were attached to the completed concrete floors on the levels above storey 20. These were cantilevered around the building by 0.5m to ensure there was enough room for the steel trusses to be lifted into place.

The steel erection was carried out using J Reddington’s tower cranes, so it was essential that the individual prefabricated truss sections did not exceed the crane’s capacity. The heaviest lift was 6.7t, while the average lift was in the region of 3.2t. After the decision was taken to install much of the cladding to the trusses offsite, again to limit the amount of work at height, the combined weight of each element was re-assessed to ensure there were no lifting issues.

According to Bourne Special Projects Divisional Director Craig Galway, once a full trial erection had been discounted, due to programme constraints, the priority was to ensure that the trusses fitted together, first time, when lifted into position. “Once we began our connection design, modelling and detailing of the frame, which is incredibly complex in its geometry, it became apparent that there would be significant amounts of butt welding in the connections, with an associated risk of heat distortion. “Where possible, the trusses were trial fitted during fabrication, but where the programme dictated that this was not practical, advanced survey techniques were employed to ensure the pieces matched when on site. During erection, not a single piece had to be lifted twice or modified, which was a fantastic achievement.”

Controlling the position of the trusses, which form the central area that goes around the core was another challenging task. Because the trusses are curved and not flat, they are on different planes in each segment and some ends of the trusses are splayed in five different angles.

Bourne’s erection team considered each lift in detail so that it could be rigged and slung so that it arrived in its final position in the correct orientation and angle. Mr Galway concludes: “Given the nature of the structure, Bourne are immensely proud to hand the frame over in its design location ahead of programme. The relationship with J Reddington has been truly collaborative and this has played a huge part in the project's success.”

The East Tower is due to be complete by end of 2021.

| Architect | Farrells |

| Structural Engineer | J Reddington |

| Steelwork Contractor | Bourne Steel |

| Main Contractor | J Reddington (JLR Group) |

| Main Client | CK Asset Holdings |