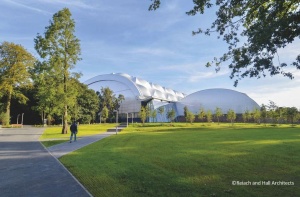

Oriam, Heriot-Watt University, Edinburgh

Structural Steel Design Awards 2017 - Award

Oriam, Scotland’s new Sports Performance Centre, comprises a full size indoor 3G synthetic pitch for football and rugby with spectator seating for 500 people, a nine-court sports hall, a 100-station fitness suite, as well as a high performance wing that includes areas for hydrotherapy, strength and conditioning, rehabilitation, offices and a classroom.

Oriam presented truly fantastic opportunities to be creative. With long spans and a simple but elegant diagram, the cross section forms the principal structural concept. Steel arches at 7m centres span over the football hall and sports hall from buttresses on each side onto a central street of piers.

The arch profile for the football hall roof offers a high rise:span ratio and considerable curvature, giving rise to a highly efficient structure with a comparatively low overall weight. The arch is a naturally efficient form allowing the structure to work primarily as axially loaded, with relatively small bending moments generated.

Tensioned PVC fabric was chosen to clad the football hall roof as it offered the necessary light transmission properties so as to limit the need for artificial lighting of the pitch space, whilst managing heat gain. It was also preferable in the structural design, given that the fabric is lightweight and forgiving to structural movements and deflections. The diagonal arrangement of arched secondary CHS members ensured that the fabric shape could be prevented from flattening under heavy imposed loading, whilst also creating interest to the roof form itself.

The sports hall roof comprises steel arches on a 7m grid, with straight secondary steel members spanning between the arches, and curved tertiary steel members spanning between secondary beams to provide intermediate support for the roof cladding. In this case, the original trapezoidal section was re-engineered to work as a standard UB section, further increasing the material and prefabrication savings.

Central piers support the ends of the football hall and sports hall arches which converge at a single point behind the listed wall, in an area known as the Street. Initially these piers were conceived as reinforced concrete elements. However, the overall programme advantages of bringing this element within the steel package were explored and, following this review, the steelwork option was selected giving both programme and cost advantages.

The roof structure acts as an umbrella over the public fitness area and high performance wing, which are both constructed as conventional steel-framed structures and accommodate the high performance spaces and the public fitness suite, café and accommodation. In the public area the tight limitations on available floor depths meant that cellular floor beams were needed to span the full width of the structure without intermediate columns, leaving the gym and café spaces completely column-free. The same was needed in the high performance wing in order to maximise the column grid spacing and minimise the disruption to the floor layouts.

The roof arch is formed from three curves meeting at tangents and, whilst this is stable once vertical, it has little structural strength in its minor axis. This meant that building the trusses flat on the ground and then lifting them vertically would require extensive temporary works, which with 13 to lift would have substantially increased the build costs. Building the trusses vertically on the ground was ruled out due to the height of any temporary frames which would have been required for temporary stability during assembly.

The solution was to utilise the permanent design for the temporary works. Simple stubs were designed to transfer the load from truss to truss with chord ties, and then match all these stubs at each truss so truss components could be connected directly to the previous truss; this allowed a full truss to be built in the air. The challenge was then how to erect the first truss! As this was at a gable the slender gable posts, which were themselves trussed, could be propped first and then roof truss segments landed on top and joined together to form one complete arched truss.

All the steel structural elements were very precisely fabricated to tight tolerances before delivery to site, which enabled a rapid waste-free assembly and a comparatively quiet construction process. This was important as the existing Centre and Academy building needed to remain open during the construction work. Erection procedures were planned in detail using 3D models.

The steel-framed structures and regular column grid arrangement for the office, café and elite sports areas are all adaptable for future changes of use.

The structural steel was efficiently engineered for fire resistance with the structural elements supporting floors required to achieve a 60 minute fire rating. For exposed elements this was achieved through the use of (high visual quality) intumescent paint. For those which are not exposed, intumescent paint with a basic finish was used.

The project team has delivered a world-class facility that also provides extensive access for the local community.

| Architect | Reiach and Hall Architects |

| Structural Engineer | Engenuiti |

| Steelwork Contractor | J & D Pierce (Contracts) Ltd. |

| Main Contractor | Bowmer & Kirkland |

| Client | Heriot-Watt University |

Judges' comment

Two parallel vaulted forms spring from a central spine; the larger one covers a football pitch, whilst the smaller covers a sports hall. The elegant lightweight steel trusses resulted from a collaborative effort by the designers and contractor, with the construction methodology informing the roof structure and supports from which it springs.

Striking and effective steelwork.