The National Robotarium, Heriot-Watt University, Edinburgh

Article in NSC May 2021

Exposed frame creates landmark research facility

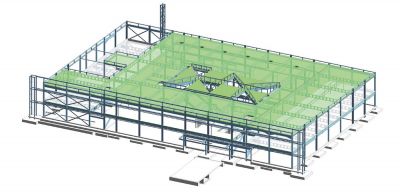

Housed in a fully-exposed steel-framed building, construction is underway on a world-leading research facility for robotics and artificial intelligence.

Based at Heriot-Watt University’s Edinburgh campus, the National Robotarium will be the largest and most advanced facility of its type in the UK. Supported by £21M from the UK Government, and £1.4M from the Scottish Government as part of the Edinburgh and South East Scotland City Region Deal, the facility will be a stand-out landmark building within the university campus.

The desired architectural vision for an industrial-looking interior has been created with exposed columns and beams throughout, while the exterior features a prominent double-skin glazed frontage, formed with a secondary lightweight steel frame. “The project suited the use of steel because of the long spans involved,” says Tetra Tech Director Stephen Alford. “Plus, in order to achieve the architectural design that incorporates exposed services, cellular steel beams and a supporting steel frame was the best option.”

The National Robotarium will be a centre of excellence for pioneering research. It will create innovative solutions to global challenges using cutting-edge research, product design and industry collaboration. Bringing together academics and global companies, the facility will provide a catalyst for entrepreneurship and is expected to deliver sustainable economic benefit to Edinburgh, the UK and beyond.

The 3,700m2 building will house three distinct research and development areas, providing bespoke facilities for Robotics & Autonomous Systems (RAS), Human Robot Interaction (HRI) and High Precision Manufacturing. It has also been announced that the National Robotarium will spearhead research into ways to manage trust between humans and autonomous systems to support adoption in scenarios that require human interaction, such as in self-driving cars or autonomous wheelchairs.

Aiming to achieve a BREEAM ‘Excellent’ rating, the project’s design focuses on sustainability and energy efficiency. In winter, the intelligent façade will provide solar heat and recycle warm air. An ecological zone will integrate sustainable urban drainage systems, while a solar PV array will be installed on the roof. Electric vehicle charging spaces will also be available. “Adding to our sustainable credentials, no materials left the site during or after our preliminary cut and fill programme that levelled the previously sloping site,” adds Robertson Construction Senior Project Manager Richard Cairns. A ground stabilisation programme was then undertaken, which involved the installation of stone piled foundations to a maximum depth of 3m.

BHC begin the steelwork erection programme with the initial braced bays

The column-free forum (atrium) will act as meeting place within the completed research centre

The 14-week steel erection programme was then able to commence in early April, work that has required BHC to fabricate, supply and erect 380t of structural steelwork. “As well as achieving the desired design, a steel-framed option was the best solution for this scheme as it offered the quickest and most cost-efficient construction programme,” adds Mr Cairns.

Based around a regular 6m column grid, with internal spans of up to 12m, all of the steelwork, including the connections, are left fully exposed in the completed scheme. Beams and columns are painted offsite with a decorative finish, which has cut-down onsite activities as the steel only needs to be touched-up with paint to repair any knocks or scratches.

The upper level of the two-storey building, which will accommodate offices, is formed with steel beams supporting metal decking and a concrete topping to create a composite flooring solution. Supporting the metal decking, the cellular beams, which are up to 610mm-deep, accommodate the building services within their depth. The use of Building Information Modeling (BIM), played a significant role in helping to achieve the coordination of services with the required penetrations in the steel beams. By accommodating services within their depth, the use of cellular beams also allowed the project to maximise floor-to-ceiling heights and thereby minimise the overall height of the building.

Overall, the building is approximately 75m-long × 45m-deep. The ground floor will house the main laboratory areas, situated around a full-height forum (atrium) that sits in the centre of the structure. Measuring 24m × 12m, the forum is a multi-purpose area, acting as a meeting point, auditorium, general break-out and circulation space. The forum is topped by a series of six triangular rooflights that will allow plenty of natural daylight to penetrate into the building.

“A lot of work was required to coordinate the frame’s bolted connections,” adds Mr Alford. “As they are all exposed, we wanted the most visually-pleasing connections, which was particularly important in the forum, where we have roof level nodes that connect up to six beams.”

Stability for the steel-framed building is derived from a combination of vertical and horizontal bracing as well as some portalised bays.

The building’s façades are all braced, including the front elevation, which features the double-skin. The main façade’s glazing creates a stand-out feature for the Robotarium and is supported by a separate lightweight box section frame that connects to the building’s main steel frame at first floor level and roof level. This secondary frame extends beyond the main building at either end to form two wings, and extends upwards beyond the roof level of the structure, before two right angled joints return the frame downwards to connect to the main steel frame. There is a 1m-deep gap between the secondary and main steel frames, inside of which there are discretely positioned maintenance walkways.

Summing up, Mr Cairns says: “The National Robotarium building is designed to be as innovative as the research taking place within its walls. The commitment to sustainability and the wellbeing of its staff and students mean the facility will be equipped with state-of-the-art technology for energy efficiency and production and will boast considerable green space. The building will be certified to ‘Fitwel’ standards, meaning its design meets strict criteria for supporting occupants’ health, wellbeing and productivity.”

The Robotarium is expected to be complete by Spring 2022.

| Architect | Michael Laird Architects |

| Structural Engineer | Tetra Tech |

| Steelwork Contractor | BHC |

| Main Contractor | Robertson Construction |

| Main Client | Heriot-Watt University |