Difference between revisions of "Barton Manor School, Canterbury"

(Created page with "==Article in [https://www.newsteelconstruction.com/wp/wp-content/uploads/2021/02/NSCFeb2021digi.pdf#page=10 NSC February 2021]== {{#image_template:image=File:Barton_Manor_Scho...") |

|||

| Line 11: | Line 11: | ||

The new [[Education_buildings|school]] will feature 7,200m<sup>2</sup> of teaching space, with both traditional teaching spaces and modern vocational training studios in a [[Braced_frames|steel-framed]] three-storey building. Vocational subjects to be taught will include catering, resistant materials, hair and beauty therapy, performing arts, information and communications technology, business and health and social care. Adjacent to the teaching block, the [[Education_buildings|school]] will also have a [[Braced_frames|steel-framed]] sports hall, that will also include a two-storey element that will accommodate a first-floor dance studio as well as changing rooms on the ground floor. | The new [[Education_buildings|school]] will feature 7,200m<sup>2</sup> of teaching space, with both traditional teaching spaces and modern vocational training studios in a [[Braced_frames|steel-framed]] three-storey building. Vocational subjects to be taught will include catering, resistant materials, hair and beauty therapy, performing arts, information and communications technology, business and health and social care. Adjacent to the teaching block, the [[Education_buildings|school]] will also have a [[Braced_frames|steel-framed]] sports hall, that will also include a two-storey element that will accommodate a first-floor dance studio as well as changing rooms on the ground floor. | ||

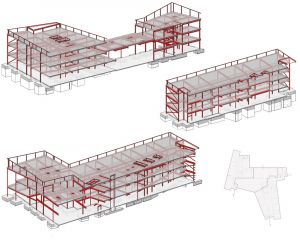

| − | {{#image_template:image=File:Barton_Manor_School-3.jpg|align=left|wrap=true|caption=Three sections of the main school building’s steel frame and a view of the school’s Z-shaped footprint|width= | + | {{#image_template:image=File:Barton_Manor_School-3.jpg|align=left|wrap=true|caption=Three sections of the main school building’s steel frame and a view of the school’s Z-shaped footprint|width=300}} |

Work on this project began in November 2019, with the demolition of the previous school buildings and then a thorough site remediation programme, which was required as asbestos was found in the ground. A major sewer previously ran beneath the site and under the proposed footprint of the main [[Education_buildings|school building]]. During the remediation programme, the sewer was diverted to run around the perimeter of the site. | Work on this project began in November 2019, with the demolition of the previous school buildings and then a thorough site remediation programme, which was required as asbestos was found in the ground. A major sewer previously ran beneath the site and under the proposed footprint of the main [[Education_buildings|school building]]. During the remediation programme, the sewer was diverted to run around the perimeter of the site. | ||

| Line 21: | Line 21: | ||

Within the building there are several [[Concept_design#Concrete or steel cores|stair cores]] and a lift core. The [[Concept_design#Concrete or steel cores|stair cores]] are [[Braced_frames|steel-framed]] with precast stairs, while the lift core also has a steel frame for [[Construction|construction]] continuity. It has block infill walls to facilitate the installation of fixings for the lift equipment. The [[Concept_design#Concrete or steel cores|cores]], however, do not provide the structure with its [[Concept_design#Structural options for stability|stability]], this is predominantly provided by [[Braced_frames#Vertical bracing|bracing]], which was required during the [[Construction|construction]] phase as well as in the completed form. The cross bracings are located within the classroom partition walls, while [[Braced_frames#Horizontal bracing|roof bracing]] is placed within the ceiling voids. However, due to the high number of windows, [[Braced_frames#Vertical bracing|bracing]] has not been viable in many locations and so some moment resisting [[Continuous_frames|continuous frames]] have been installed. | Within the building there are several [[Concept_design#Concrete or steel cores|stair cores]] and a lift core. The [[Concept_design#Concrete or steel cores|stair cores]] are [[Braced_frames|steel-framed]] with precast stairs, while the lift core also has a steel frame for [[Construction|construction]] continuity. It has block infill walls to facilitate the installation of fixings for the lift equipment. The [[Concept_design#Concrete or steel cores|cores]], however, do not provide the structure with its [[Concept_design#Structural options for stability|stability]], this is predominantly provided by [[Braced_frames#Vertical bracing|bracing]], which was required during the [[Construction|construction]] phase as well as in the completed form. The cross bracings are located within the classroom partition walls, while [[Braced_frames#Horizontal bracing|roof bracing]] is placed within the ceiling voids. However, due to the high number of windows, [[Braced_frames#Vertical bracing|bracing]] has not been viable in many locations and so some moment resisting [[Continuous_frames|continuous frames]] have been installed. | ||

| + | |||

| + | The main [[Education_buildings|school building]] and the two-storey part of the sports hall have both used a [[Floor_systems#Precast units|precast flooring]] solution supported by steel beams. “The [[Floor_systems#Precast units|precast floors]] work well with steel in terms of quality control and speed. [[Steel_construction_products#Decking for floors|Metal decking]] with concrete was considered, but tends to be too thin for the multitude of uses we required,” says Mr Moynihan. | ||

<gallery mode="packed" heights=250px> | <gallery mode="packed" heights=250px> | ||

Image:Barton_Manor_School-2.jpg|Strategically placed [[Braced_frames#Vertical bracing|bracing]] provides the [[Concept_design#Structural options for stability|stability]] | Image:Barton_Manor_School-2.jpg|Strategically placed [[Braced_frames#Vertical bracing|bracing]] provides the [[Concept_design#Structural options for stability|stability]] | ||

| Line 27: | Line 29: | ||

</gallery> | </gallery> | ||

<br> | <br> | ||

| − | |||

| − | |||

The installation of the [[Floor_systems#Precast units|precast flooring planks]] required a lot of coordination between steelwork contractor H Young Structures and the project’s precast concrete installer. The steelwork was generally [[Construction#Steel erection|erected]] to the full height of the structure, with the roof elements left off to allow the planks to be lifted into place. Once the flooring was installed, H Young Structures’ team followed on behind to complete the steel frame. | The installation of the [[Floor_systems#Precast units|precast flooring planks]] required a lot of coordination between steelwork contractor H Young Structures and the project’s precast concrete installer. The steelwork was generally [[Construction#Steel erection|erected]] to the full height of the structure, with the roof elements left off to allow the planks to be lifted into place. Once the flooring was installed, H Young Structures’ team followed on behind to complete the steel frame. | ||

Latest revision as of 14:20, 5 February 2021

Article in NSC February 2021

Steel passes school exams

Structural steelwork has proven to be the right choice for the construction of a new school in the cathedral city of Canterbury.

A partnership between Kent County Council, the Department for Education and Barton Court Academy Trust is constructing a new school in Canterbury. Being built on the site of the former Chaucer Technology School, Barton Manor School is due to open in September 2022, and will provide teaching space for 1,050 pupils aged between 11 and 18.

In order to meet the scheduled school opening date, it was important to choose construction materials that could form the architectural design economically and swiftly. “Speed of construction is always important and building with a steel-framed solution is quicker than other methods, especially during the inclement winter months,” says Kier Project Manager Jamie Hawkins. “We also have some 18.5m-long spans in the sports hall, and these would have been difficult to form in anything other than steel.”

Malachy Walsh and Partners’ Associate Director Tim Moynihan agrees and adds: “Steel provides security of quality and speed, unlike concrete there is little or no risk of a member not reaching the required quality and having to be recast as sometimes occurs with concrete elements.”

The new school will feature 7,200m2 of teaching space, with both traditional teaching spaces and modern vocational training studios in a steel-framed three-storey building. Vocational subjects to be taught will include catering, resistant materials, hair and beauty therapy, performing arts, information and communications technology, business and health and social care. Adjacent to the teaching block, the school will also have a steel-framed sports hall, that will also include a two-storey element that will accommodate a first-floor dance studio as well as changing rooms on the ground floor.

Work on this project began in November 2019, with the demolition of the previous school buildings and then a thorough site remediation programme, which was required as asbestos was found in the ground. A major sewer previously ran beneath the site and under the proposed footprint of the main school building. During the remediation programme, the sewer was diverted to run around the perimeter of the site.

Kier then installed pad foundations and ground beams in readiness for the steelwork erection programme to begin. However, to give the steel a helping hand and make it easier to achieve the required fast construction programme, the ground floor slab for the teaching block was also installed during the groundworks phase. “This gave the steel erectors a flat, clean and dry surface to run their MEWPs along during their programme, which helped to ensure they completed the work on schedule,” adds Mr Hawkins.

The main school building is a sort of Z-shaped structure with a full-height atrium, containing the dining room and a sixth form social area, at its centre. Next to the dining area there is an activities hall, which is a double height space and represents the only part of the main school building that is two-storeys high. Forming this area’s column-free space, is a series of 12m-long UB roof rafters. The classrooms generally radiate outwards, on all three floors, from the main atrium and tend to have regular widths, although some are longer than others.

As the plan shape of the school is not very regular, some of the steel connections are not at 90 degrees to each other. “This is where our BIM project collaboration was useful, as it allowed these details to be inspected closely,” explains Mr Moynihan. Adding architectural interest to the lower parts of the main school building, some columns are circular hollow sections that will remain exposed in the completed scheme. On the upper floor, these members will not be on view and consequently they change to standard UC sections.

Within the building there are several stair cores and a lift core. The stair cores are steel-framed with precast stairs, while the lift core also has a steel frame for construction continuity. It has block infill walls to facilitate the installation of fixings for the lift equipment. The cores, however, do not provide the structure with its stability, this is predominantly provided by bracing, which was required during the construction phase as well as in the completed form. The cross bracings are located within the classroom partition walls, while roof bracing is placed within the ceiling voids. However, due to the high number of windows, bracing has not been viable in many locations and so some moment resisting continuous frames have been installed.

The main school building and the two-storey part of the sports hall have both used a precast flooring solution supported by steel beams. “The precast floors work well with steel in terms of quality control and speed. Metal decking with concrete was considered, but tends to be too thin for the multitude of uses we required,” says Mr Moynihan.

Visualisation of the completed school

The installation of the precast flooring planks required a lot of coordination between steelwork contractor H Young Structures and the project’s precast concrete installer. The steelwork was generally erected to the full height of the structure, with the roof elements left off to allow the planks to be lifted into place. Once the flooring was installed, H Young Structures’ team followed on behind to complete the steel frame.

Summing up, Ms Cardus, Executive Headteacher of Barton Court Academy Trust says: “The school is a truly exciting project for Barton Court Academy Trust and the local community. It has been an amazing opportunity to design a school from inception which can deliver our vision for excellence, collaborative learning and creativity. The Trust has named the new school Barton Manor School and it will provide Canterbury and the local area with much needed secondary school places.”

| Architect | Noviun Architects |

| Structural Engineer | Malachy Walsh and Partners |

| Steelwork Contractor | H Young Structures |

| Main Contractor | Kier |

| Main Client | Kent County Council |