Difference between revisions of "Dixons Allerton Academy, Bradford"

| Line 50: | Line 50: | ||

|} | |} | ||

| − | [[Category:Case studies | + | [[Category:Case studies - Education buildings]] |

Revision as of 12:16, 12 March 2019

Article in Steel construction – education sector supplement, January 2013

In the frame

The use of structural steelwork has played a crucial and significant role in the construction of a flagship academy in Bradford.

A number of factors come into play when deciding on a material for a project’s structural frame. Quality of construction, future flexibility and cost are always major considerations, but on a school project in Bradford another criteria was deemed equally as important.

For Dixons Allerton Academy the project team wanted a frame that was quick to erect and, importantly, formed a flat soffit. The thinking behind this decision is that it helps with the installation of services and partition walls, making the construction programme quicker. This was particularly important at this academy as it will be mechanically ventilated, so consequently there is a fair amount of associated ducting to be installed. “A flat soffit with no down-stand beams certainly means the follow on trades can complete their work more quickly and efficiently once the steel frame has been erected,” explains Jonathan Pye, BDP Project Director. BDP designed a Slimflor steel frame using tubular steel box sections, with each beam having plates welded to the underside to support concrete floor planks, so ensuring the desired flat soffit.

Speed of construction is of utmost importance on all projects and this job was no different. The new school is scheduled to open in time for the 2013 autumn term, so a quick steel erection programme (completed by Elland Steel Structures in just 17 weeks) was a bonus to all concerned.

Main contractor Wates Construction was keen on utilising a steel framed design as it has successfully constructed a number of school projects in recent times, all of which have employed structural steelwork. However, this project is slightly different as it is one of the last Building Schools for the Future (BSF) schemes. “Because of this it has a bespoke steel framed design, and externally we’ve gone for – at the client’s request – a robust brickwork cladding,” says Mark Powell, Wates Construction Project Manager.

Specialising in health and science, the new Dixons Allerton Academy in Bradford will accommodate 1,886 students from ages three right through to 19. This will break down to 26 nursery places; 420 primary and preschool places, and 1,440 secondary places. To accommodate such an array of age groups, the school’s design incorporates classrooms on a standard grid, but some feature moveable partitions – which is easier to do with a steel frame – allowing two classes to be combined into one larger room as required. “Future flexibility is one of the main design criteria for modern schools,” says Mr Pye. “None of the partition walls are load bearing and so they could be removed, allowing the classrooms to be reconfigured.”

The new building consists of a long curved three-storey secondary school element, with a two-storey primary school attached to its northern elevation. The primary and secondary schools are linked on two levels and share a common entrance. The secondary part of the school houses a sports hall at one end, and here, because of the sloping topography, the building is stepped. The ground floor ends at a retaining wall beyond which sits the sports hall, which is linked directly into the rest of the school’s first floor level.

Stability for the steel frame is derived from bracing which is positioned at various locations around the structure, mostly inside internal walls.

The elongated secondary school building includes two large atriums, both featuring skylights which will allow natural daylight to penetrate the inner structure. Classrooms are arranged predominantly into three rows, with two adjacent corridors either side of a central spine row of classes. The passageways follow the curving shape of the building and separate the inner classrooms from the two perimeter rows of classes. Because of the long span steel design, the inner or spine row of classes could be removed in the future, as there are no column lines in their partition walls. “The design has accommodated IT classes in the spine, as these don’t necessarily need direct daylight,” explains Paul Owen, BDP Architect Associate.

The exceptions to the three classroomed row configuration are the atrium locations, where only the perimeter rows continue either side of the void, and the sports hall where only one row of classes continues along the northern elevation.

Because the main curving secondary school building is so long, it has structurally been split into three manageable segments by two movement joints. The primary school, although attached, is in fact a standalone structure and is separated from the rest of the school by another movement joint.

The primary school is arranged in a square shape around an inner courtyard. This area has an internal and external element, and will be used as a recreational area overlooked by the classrooms. An additional external play area has been accommodated along the front portion of the primary school’s upper level.

When the Dixons Allerton Academy is completed in August, the existing school buildings will be demolished to make way for new sports pitches, which will also be available for community use.

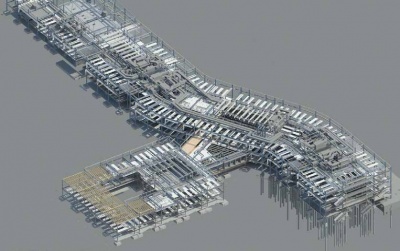

Academy provides BIM flagship

By providing a multi-disciplinary service coupled with a Building Information Modelling (BIM) workflow, BDP says it was able to play to its strengths on the Dixons Allerton project. At an early stage, the structural team at BDP Manchester took ownership of the architect’s design model (BDP Sheffield), which improved communication, and reduced re-draw time. As each profession developed the model, clash detection became an integral part of the design process in order to produce coordinated and accurate information in the handover to the various steelwork contractors.

All construction documentation was produced directly from the data-rich 3D model; from the architect’s planning submission drawings, through schedules and quantities, to detailed design. “By referencing live information, it became quickly apparent when a call across the Pennines was needed to tidy up a detail, five minutes later... issued resolved,” says Mr Pye. But the use of BIM not only improved communication and co-ordination within the design team, it also offered additional outputs visually, through 4D construction sequencing.

| Architect | BDP |

| Structural Engineer | BDP |

| Steelwork Contractor | Elland Steel Structures |

| Main Contractor | Wates Construction |

| Client | Integrated Bradford |