Specification of bridge steelwork

This article provides guidance on the specification of bridge steelwork in the UK, for bridges designed in accordance with the Eurocodes.

The purpose of a structural steelwork specification is to state what materials and products should be used and how work (fabrication and erection) should be carried out, in order to ensure that the completed structure meets the designer’s assumptions and the client’s needs.

The principal document for the technical requirements for bridge steelwork is BS EN 1090-2[1] but the complete ‘execution specification’ comprises a range of contractual documents, including drawings, a general specification with technical requirements for supply of materials and products and for workmanship, and project-specific requirements for the individual structure. Project-specific requirements may be influenced by client authority requirements such as the Specification for Highway Works[2], or Network Rail's Specification for structural steelwork[3] which is now very similar.

[top]British standards for steelwork (issued as BS EN)

Rules for the design of steelwork are given in Eurocode 3 Design of steel structures. Within Part 1-1[4] of that Eurocode, the following basic assumption is stated: "fabrication and erection complies with EN 1090" (this assumption is maintained in Eurocode 3 Part 2[5]).

BS EN 1090, Execution of steel structures and aluminium structures, consists of four parts, of which two are relevant for steel bridges:

- Part 1: Requirements for conformity assessment of structural components[6]

- Part 2: Technical requirements for steel structures[1]

Conformity with the requirements in Part 1[6]

(which are general statements, referring to the other Parts for detailed technical requirements), when formally declared, permits UKCA marking of the structure.

The technical requirements in Part 2[1] are comprehensive, covering all types of structural steel (including stainless steel) and types of structure (buildings, bridges, masts, cranes etc.). It includes references to British standards for products, welding, testing and corrosion protection. Products manufactured in accordance with UK Designated Standards are individually UKCA marked.

Because of its universal coverage, BS EN 1090-2[1] has many instances where an execution specification needs to give additional requirements or to choose optional requirements, to suit the particular structure. These additional and optional requirement choices are especially necessary for bridge steelwork, where high quality products and workmanship are needed.

For projects where there are no additional Client requirements, SCI publication P382, Model Project Specification for the Execution of Steelwork in Bridge Structures (MPS) provides sufficient guidance to complete a steelwork specification that provides the additional and optional requirement choices prompted by BS EN 1090-2[1].

[top]Specification for Highway Works

For projects executed in the UK for Highways England and Network Rail (and for Devolved and Local Authorities adopting their requirements), those Clients have published specification documents and notes for guidance for the execution of steelwork to address quality differentiation and to specify directly a number of the choices left open by BS EN 1090-2[1], e.g.

- Series 1800 of the Specification for Highway Works (SHW)[2]

- Series NG1800 of the Specification for Highway Works (SHW)[7].

However, there is still some project-specific information that must be provided in addition to the Client documents. Series NG1800[7] includes a sample contract specific Appendix 18/1 to make the minor adjustments to suit different bridge projects. In addition, the Steel Bridge Group has produced a short guidance document SCI publication P418 to assist with the completion of Appendix 18/1. Reference is made in P418 to another SCI publication P185, Steel Bridge Group: Guidance Notes on Best Practice in Steel Bridge Construction, which provides extensive complementary guidance.

BS EN 1090-2[1] specifies four different ‘execution classes’, for which the strictness of the requirements (particularly for welded details) increases from EXC1 to EXC4. The classes may be defined either for the structure as a whole or for parts of the structure. For most bridge structures, the adoption of EXC3 for the whole structure is appropriate. This is adequate for most details in ‘ordinary’ highway bridges and the adoption of a universal class offers simplicity, clarity and economy.

[top]Particular requirements addressed within the SHW

[top]Constituent products

The SHW[2] expects that the grade and quality of most products will be given on drawings, with reference to the product standards that are listed within the reference standards in BS EN 1090-2[1]. Some particular requirements, such as surface conditions, are stated, along with requirements for traceability (bridge steelwork generally requires traceability by piece for the principal components).

[top]Preparation and assembly

Preparation and assembly requirements are of special concern for fatigue-susceptible structures such as bridges. The SHW[2] gives requirements related to the condition of surfaces and edges.

[top]Welding

Weld sizes and types are generally specified on drawings by symbols in accordance with the relevant standard. Welding is a relatively expensive operation and weld sizes should not be over-specified.

The SHW[2] clarifies where pre-production tests are needed, such as for shear stud connectors, the requirements for tack welds and temporary attachment (which can have a detrimental effect on fatigue life) and where additional operations such as grinding flush are required. Generally, the weld acceptance levels for EXC3 are sufficient for most fatigue details but should more onerous criteria be needed, provision is made for adding appropriate requirements. Guidance on fitness-for-purpose specification of workmanship and acceptance criteria are given in PD 6705-2[8].

[top]Mechanical fastening

Preloaded bolts are almost always used in bridges. Where non-preloaded bolts are used, the SHW[2] requires the use of locking devices.

BS EN 1090-2[1] does not provide requirements for one of the tightening methods commonly used in the UK, the part-turn method (the ‘requirements’ for the 'combined method’ require a higher bedding torque and require greater classification of bolt properties than in commonly available bolts in the UK and are thus not applicable for the part-turn method). The SHW[2] includes additional requirements for the part-turn method, which have been validated for bolts to BS EN 14399-3[9].

BCSA publish a Model Specification for the Purchase of Structural Bolting Assemblies and Holding Down Bolts.

[top]Erection

For bridges, the erection method usually has a significant influence on the final state of stress of the structure, as well as necessitating consideration of the stability in the part-erected condition. An erection method statement is therefore an essential part of contract documentation. The SHW[2] includes a number of clauses to clarify the requirements.

General guidance on erection methods is given in the BCSA guide to the erection of steel bridges.

[top]Surface treatment

To protect against corrosion, bridge steelwork is usually either painted or weathering steel is used. In either case, BS EN 1090-2[1] covers the required surface preparation. The SHW[2] confirms the preparation grade that is needed and offers additional requirements for sealing of spaces.

Where painting is called for, the requirements of the corrosion protection system are to be stated as performance requirements. Reference may be made to Series 1900 of the Specification for Highway Works[10] and the associated Notes for Guidance[11]

[top]Geometrical tolerances

Essential and functional tolerances are generally given in an Annex to BS EN 1090-2[1]. Specific additional requirements for bridge structures are given in the SHW[2].

[top]Inspection, testing and correction

Generally, the scope of inspection for EXC3 will be sufficient but where additional testing is appropriate, the SHW[2] provides the means to specify it. Production tests on headed shear stud connectors (not covered in BS EN 1090-2[1]) are specified.

[top]Quality assurance

BS EN 1090-2[1] lists a number of procedures that must be documented for classes EXC2 and higher. It also provides the option to specify a quality plan for the works. It is usual to require a quality plan for bridge structures and this is confirmed in the SHW[2].

BS EN 1090-1[6] states that conformity with the Standard (both Parts 1 and 2, in the case of steel structures) is demonstrated by initial type testing (ITT) and factory production control (FPC). Where these have been demonstrated, the steelwork may be UKCA marked. For bridge steelwork, the characteristics of the constituent products will normally have been demonstrated by production in accordance with product standards (and thus ITT has been demonstrated). A FPC system conforming to the requirements of BS EN ISO 9001[12] is considered satisfactory for conformity (although other systems could also be satisfactory).

BS EN ISO 9001[12] gives requirements for quality management systems. This Standard may be used in any industry. National Highways (NH), formerly Highways England, has promoted development of a series of National Highways Sector Schemes (NHSS) to aid certification bodies in interpreting the requirements of BS EN ISO 9001[12] for particular sectors of activity for transportation infrastructure. The BCSA and the Steel Construction Certification Scheme (SCCS) have been active in assisting NH in developing schemes for structural steelwork (NHSS 20[13]), for the supply of mechanical fasteners (NHSS 3 [14]), for the supply of structural steel products (NHSS 3B [15]) and for corrosion protection (NHSS 19A[16]).

In addition, BCSA operates the Register of Qualified Steelwork Contractors for Bridgeworks (RQSC). A company qualifies for inclusion after being assessed by specialists who check the company’s financial and technical resources as well as track record and employed personnel. Companies are categorised in terms of the work they can execute technically, and the maximum size of contract they should handle.

For highway structures, the SHW Series 1800[2] requires certification in accordance with NHSS 3[14] , NHSS 3B[15] and NHSS 20[13]. The SCCS is accredited for this certification. In addition, the SHW Series 1800[2] requires that only companies listed on the RQSC for Bridgeworks for the type and value of work to be undertaken shall be employed for the fabrication and erection of bridgeworks.

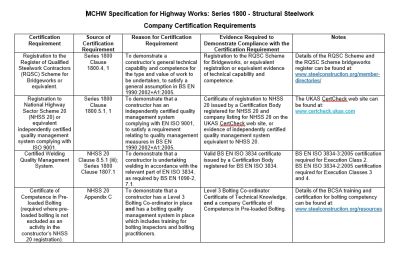

[top]SHW Series 1800[2] certification requirements clarified

BCSA has been made aware of a number of steelwork contractors who intend working on schemes where the National Highways Specification Series 1800[2] for structural steelwork applies who are confused over the certifications that are relevant to Series 1800[2] requirements.

In particular there is some misunderstanding over the certification requirements relating to the Register of Qualified Steelwork Contractors (RQSC) bridgeworks register and National Highway Sector Scheme 20 (NHSS 20)[13]. Some contractors believe that RQSC bridgeworks register certification (Series 1800[2], Cl 1800.4, 1) and NHSS 20[13] certification (Series 1800[2], Cl 1800.5.1, 1) are equivalent, and that only one is required to meet Series 1800[2] requirements.

This is not correct as the two relate to demonstrating different attributes of a contractor. Both certifications are necessary should a contractor choose to use these as a means of demonstrating compliance with the relevant Series 1800[2] requirements.

RQSC bridgeworks register certification demonstrates a contractor’s general technical capability and competence to undertake the specific works required for a contract.

NHSS 20[13] certification demonstrates that a contractor operates an independently certified quality management system complying with BS EN ISO 9001[12] that is relevant to the execution of structural steelwork.

There are other certification requirements that are described in Series 1800[2] that a contractor should have in place and are described in a schedule available here.

The schedule is primarily intended as a reference for contractors and for those supervising contracts, to help understand the various certifications that are required by Series 1800. The schedule will also to help:

- auditors understand the Series 1800[2] certification related requirements when auditing steelwork contractors for NHSS 20[13], and

- in answering any queries relating to these requirements that may be raised by steelwork contractors.

[top]References

- ↑ 1.00 1.01 1.02 1.03 1.04 1.05 1.06 1.07 1.08 1.09 1.10 1.11 1.12 BS EN 1090-2:2018 Execution of steel structures and aluminium structures. Technical requirements for steel structures. BSI

- ↑ 2.00 2.01 2.02 2.03 2.04 2.05 2.06 2.07 2.08 2.09 2.10 2.11 2.12 2.13 2.14 2.15 2.16 2.17 2.18 2.19 2.20 2.21 2.22 Manual of Contract Documents for Highway Works (MCHW). Volume 1: Specification for Highway Works. Series 1800 Structural Steelwork. April 2021, TSO

- ↑ NR/L2/CIV/140/1800C Specification for structural steelwork, Network Rail, June 2016,

- ↑ BS EN 1993-1-1:2005+A1:2014, Eurocode 3: Design of steel structures. General rules and rules for buildings, BSI

- ↑ BS EN 1993-2:2006. Eurocode 3: Design of steel structures, Steel Bridges. BSI

- ↑ 6.0 6.1 6.2 BS EN 1090-1:2009+A1:2011 Execution of steel structures and aluminium structures. Requirements for conformity assessment of structural components. BSI

- ↑ 7.0 7.1 Manual of Contract Documents for Highway Works (MCHW). Volume 2: Notes for Guidance on the Specification for Highway Works. Series NG 1800 Structural Steelwork. April 2021, TSO

- ↑ PD 6705-2:2020. Structural use of steel and aluminium. Execution of steel bridges conforming to BS EN 1090-2. Guide. BSI

- ↑ BS EN 14399-3:2015. High-strength structural bolting for preloading. System HR. Hexagon bolt and nut assemblies. BSI

- ↑ Manual of Contract Documents for Highway Works: Volume 1 - Specification for Highway Works, Series 1900 Protection of steelwork against corrosion, August 2014, TSO

- ↑ Manual of Contract Documents for Highway Works: Volume 2: Notes for Guidance on the Specification for Highway Works, Series 1900: Protection of Steelwork Against Corrosion, August 2014, TSO

- ↑ 12.0 12.1 12.2 12.3 BS EN ISO 9001:2015. Quality management systems. Requirements. BSI

- ↑ 13.0 13.1 13.2 13.3 13.4 13.5 NHSS 20: National Highways Sector Schemes for Quality Management in Highway Works, 20. The Execution of Steelwork in Transportation Infrastructure Assets, Issue 6 (9001:2015), February 2023

- ↑ 14.0 14.1 NHSS 3: National Highways Sector Schemes for Quality Management in Highway Works, 3. The Stocking and Distribution Activities for Mechanical Fasteners, Issue 5 (9001:2015), February 2023

- ↑ 15.0 15.1 NHSS 3B: National Highways Sector Schemes for Quality Management in Highway Works, 3B. The Stocking and Distribution Activities for Structural Steel Products, Issue 4 (9001:2015), February 2023

- ↑ NHSS 19A: National Highways Sector Schemes for Quality Management in Highway Works, 19A. For corrosion protection of ferrous materials by industrial coatings. Issue 7 (9001:2015), 30 June 2023

[top]Resources

- Hendy, C.R.; Iles, D.C. (2015) Steel Bridge Group: Guidance Notes on best practice in steel bridge construction (6th Issue). (P185). SCI

- Guidance Note 3.01 Structural steels

- Guidance Note 3.05 Surface defects on steel materials

- Guidance Note 3.06 Internal defects in steel materials

- Guidance Note 3.07 Specifying steel material

- Guidance Note 4.02 Weld procedure tests

- Guidance Note 4.05 Specification of tension bar components

- Guidance Note 5.03 Geometrical tolerances

- Guidance Note 5.05 Marking of steelwork

- Guidance Note 6.01 Control of weld quality and inspection

- Guidance Note 7.05 Installation of preloaded bolts

- Guidance Note 8.01 Preparing for effective corrosion protection

- Guidance Note 8.05 High performance paint coatings

- Hendy, C.R.; Iles, D.C. (2012) Steel Bridge Group: Model Project Specification For the Execution of Steelwork in Bridge Structures. (P382). SCI

- Hendy, C.R.; Iles, D.C.; Palmer, I. (2017) Steel Bridge Group: Completion of Appendix 18/1. (P418). SCI

- Steel Bridges: A practical approach to design for efficient fabrication and construction, 2010, (Publication no. 51/10), BCSA

- Guide to the Erection of Steel Bridges, 2005, (Publication no. 38/05), BCSA

- Model Specification for the Purchase of Structural Bolting Assemblies and Holding Down Bolts, Issue 14, BCSA, 2023

- Model Specification for the Purchase of Structural Tension Assemblies, BCSA, 2015

[top]See also

- Surface preparation

- Corrosion protection

- Welding

- Preloaded bolting

- Material selection and product specification

- Weathering steel

- Shear connection in composite bridge beams

- Fatigue design of bridges

- Design for steel bridge construction

- Fabrication

- UKCA marking