Preston Western Distributor

Article in NSC June 2021

Three bridges for Preston link

The installation of the first of three steel bridges that will form key elements of a major infrastructure project in Lancashire has been completed.

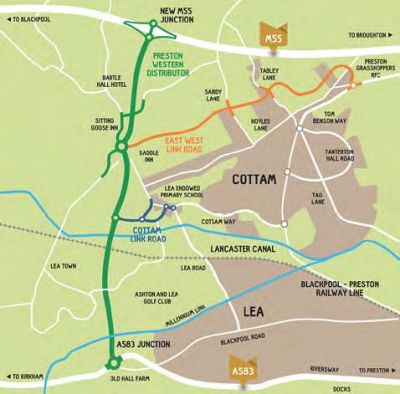

Steel construction is playing an integral role in the building of the Preston Western Distributor, which on completion will link the A583 with the M55 motorway. The project will create a new western bypass for Preston and is one of the largest ongoing road schemes in Lancashire. Working on behalf of main contractor Costain, Cleveland Bridge has installed one steel bridge structure and will eventually complete another two as part of its overall package.

The scheme has been made possible due to the partnership agreement between the Lancashire Enterprise Partnership, Lancashire County Council, Preston City Council, South Ribble Borough Council, central government and Homes England. Funding is coming from the Department for Transport, Highways England, the county council, City Deal and the Lancashire Growth Deal.

According to Lancashire County Council, the road project is needed as the transport network serving Preston and the wider area is becoming increasingly congested. A council spokesperson said: “As the working age population in Lancashire is decreasing, we need to build on the sustained economic growth to keep young people in the area and bring in more skilled workers. We need to make sure that the road infrastructure supports our ambitious plans across North West Preston including 5,500 new homes.”

Spanning the Lancaster Canal and the Preston to Blackpool railway line and positioned at the midway point of the road scheme, the 233m-long Lea Viaduct was the first steel bridge structure to be installed on the project. This five-span structure required 2,607t of S355 grade weathering steel.

“The three steel beamed structures on the project span a variety of existing infrastructures such as the canal, motorway, and railway line. Weathering steel was the obvious choice for the design of these structures as it offers a low maintenance solution that is quickly assembled once delivered to site,” says Costain Senior Engineer Rosey Thurling. “At Lea Viaduct, where the road passes over the Preston – Blackpool Railway line, steel beams with a curved soffit have been designed to minimise the overall height, therefore reducing the quantity of imported aggregate required across the scheme.”

A 600t-capacity crawler crane was used for the installation of the Lea Viaduct

One of the main bridge girders of the Lea Viaduct is lifted into place

Working in partnership with project engineers Jacobs and Atkins, Cleveland Bridge designed and fabricated the Lea Viaduct in five sections, each made up of five pairs of girders. Installed during a six-week programme utilising a 600t-capacity crawler crane, Cleveland Bridge says the installation called for considerable expertise and experience as the bridge spans both water and railway lines, while the work site could only be accessed via a tight country lane.

Explaining the company’s fabrication process for this project and in general, Cleveland Bridge Project Manager Gordon Davies says: “Our bridges are fabricated from steel plate, blast prepared, profile cut and holes drilled to the correct dimensions to form three pieces: a top and bottom flange and a central section to join the two known as the web. The top flange being the first piece, is placed on a roller flat bed and the web positioned vertically and central to it, and then tack welded to form a ‘T’. The process is repeated with the bottom flange laid on the roller bed. The ‘T’ is lifted, rotated and placed on the newly positioned flange and tack welded. This has now formed the ‘I’ section and is known as a carcass, which then moves through a welding machine, which completes the initial process to the clients stipulated specification.”

A lot of a bridge fabricators' work is a variation on a general set pattern, as onward stages involve adding various steel components to form stiffeners, bracings, connections for later use both within the factory and on site. On a composite bridge deck such as the Lea Viaduct, composite action between the reinforced concrete deck slab and the longitudinal girders is achieved by means of shear connectors welded on the top flanges of the steel girders. Hooped shear connectors were also fitted at the girder ends to help form the connection with the integral concrete abutments.

Once fabrication was complete for the Lea Viaduct, single girders were paired with another and cross braced together, before being transported to site for installation.

Due to complete next month (July) Cleveland Bridge is currently erecting the steelwork for the Becconsall Viaduct, which forms the central element for a new junction on the M55 at the northern end of the scheme. Requiring 514t of weathering steel, the Becconsall Viaduct is 45m-long single span structure.

The third and final structure is the Savick Brook bridge, where the steel erection is due to complete in March 2022. This is a 278m-long six-span bridge that spans a navigable channel and floodplain at the southern end of the scheme.

Summing up, Costain Construction Manager Steve Webster says: “The use of steel beams for the Lea Viaduct has been fundamental in providing the most slender bridge profile. This ensured the vertical alignment of the roads could be lowered as far as possible, reducing scheme costs and improving the carbon footprint by reducing the volume of earthworks materials required.”

The Preston Western Distributor is due to be open by early 2023.

| Structural Engineer | Jacobs, Atkins |

| Steelwork Contractor | Cleveland Bridge |

| Main Contractor | Costain |

| Main Client | Lancashire County Council |