Recycling and reuse

Scarcity of resources and the need to reduce the environmental impacts of winning and processing construction materials and products is placing a greater emphasis on resource efficiency within the construction industry. It is estimated that the UK construction industry consumes some 400Mt of materials annually and generates some 120Mt of (construction, demolition and excavation) waste, of which 5Mt ends up in landfill. Therefore, there is significant scope for improving resource efficiency within the industry, particularly at the end-of-life of buildings.

Importantly, the majority of the construction and demolition arisings are heavy bulk wastes such as concrete, masonry and asphalt which are generally crushed and downcycled into lower grade applications such as general fill. Although landfill is avoided, downcycling is low-grade recycling and low down on the UK waste hierarchy. More has to be done to encourage reuse and higher grade recycling of these problem materials.

The developing Circular economy agenda, particularly the Action plan launched by the EU in 2016, is also focussing greater attention on waste, resource efficiency and recycling and reuse in construction.

Major improvements in materials resource efficiency are possible without increasing cost by:

- Reducing the quantity of materials being sent to landfill during the construction process by ‘designing out waste’ and effective site waste management

- Reusing, recycling and recovering waste material as appropriate

- Utilising materials and products with a high recycling and reuse potential.

The focus of this article is the second and third of these; reuse and recycling. These are also fundamental to achieving the goal of the circular economy.

[top]What is recycling and reuse?

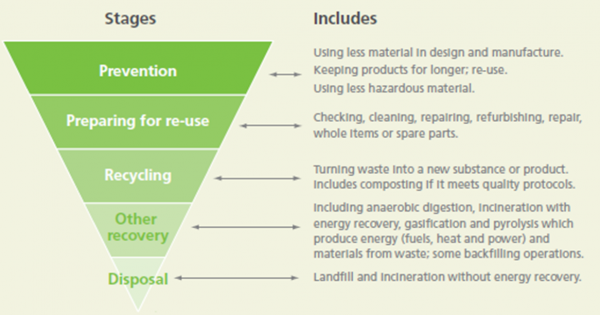

Reuse and recycling are key stages of the UK Waste Hierarchy and are the preferred options after all has been done to prevent waste in the first place through design and manufacture.

Reusing and recycling construction products avoids or reduces waste and saves primary resources. By using materials that have a greater potential for reuse and recycling, it is more likely that the value of these products at their end-of-life will be realised and extended in future applications.

Some materials are more recyclable than others, for example the process of recycling may be easier or the recycled product may have the same or a higher economic value than the original product. It is therefore more likely that such products will be efficiently recycled in the future and designers should be encouraged to use such products.

[top]Recycling

By recycling, we contribute to more sustainable development by eliminating or reducing waste and by saving primary resources. Also, recycling some materials, like metals, saves energy (and reduces carbon emissions) since it requires less energy to re-melt scrap than it does to produce new metal from primary resources, i.e. iron ore.

The benefits of recycling are well understood and include:

- Reducing waste, i.e. diverting waste from landfill

- Saving primary resources, i.e. substituting primary production

- Saving energy and associated greenhouse gas emissions through less energy intensive reprocessing.

Although these benefits apply to many commonly recycled materials, there are some important differences in the properties of materials that influence the environmental benefit of recycling and particularly how these benefits are quantified.

Metals, for example, are infinitely recyclable, i.e. they can be recycled again and again into functionally equivalent products - this is the most environmentally beneficial form of recycling.

Other products are ‘down-cycled’ into new products that are only suitable for lower grade applications because the recycled product has different, usually lower, material properties. Although waste is diverted from landfill by down-cycling, only lower grade primary resources are saved. For example crushing bricks and concrete for hardcore, sub-base or general fill saves aggregates but doesn’t save the resources required to make new bricks or new concrete.

For recycling to be sustainable in the long term, it is important that the recycling process is financially viable. This is frequently the biggest hurdle to recycling, particularly for products and materials that are down-cycled into lower grade, low value applications.

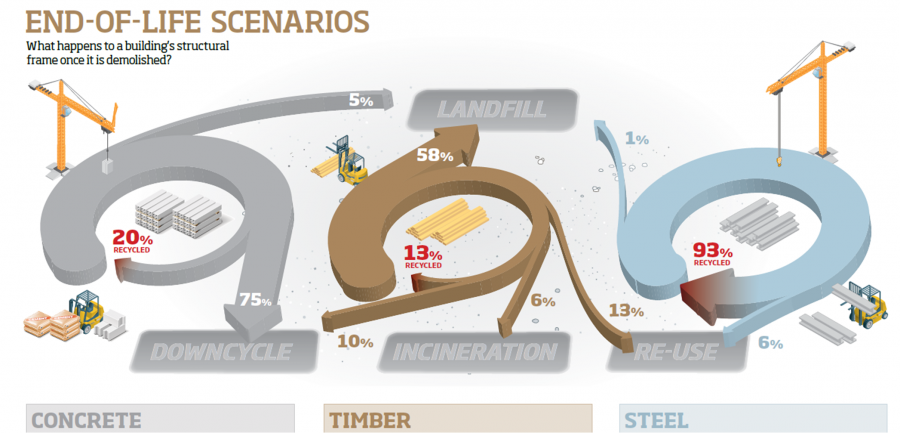

Current end-of-life scenarios for three of the most common construction materials; concrete, timber and steel are shown. The table describes the end-of-life outcomes of these materials against the established UK Waste Hierarchy.

The challenge in assessing the embodied environmental impacts of products therefore is how the benefits of highly recyclable materials and reusable products should be quantified and assessed relative to products that are downcycled or landfilled. This is a new discipline for designers who are used to thinking about how buildings are constructed, i.e. put together, but have generally not been concerned about how they are deconstructed (taken apart) so that their constituent parts can either be easily recovered for reuse or recycling.

If the recyclability and reusability of construction products at the end-of-life of buildings are not considered in assessing building designs, this effectively equates products that are downcycled or landfilled with products that are truly recycled or reused. This is why all recent guidance and standards for the environmental assessment of buildings advocate a robust whole life assessment that includes assessment of these aspects of the building.

A case study on recycling of steel at the Teesside Meltshop at Lackenby can be accessed by clicking here.

[top]How to account for the benefits of recycling?

Life cycle assessment (LCA) is widely recognised as the best and most rigorous tool for assessing the environmental impacts of products and services.

In LCA the benefit of recycling may be considered as an ‘environmental credit’ or benefit. Recycling avoids the higher burdens of primary material production but this environmental saving lies in between two adjoining product systems, i.e. the upstream system which produced the scrap materials, e.g. demolition of a building; and the downstream system which will consume the recycled material, e.g. steel production. How this ‘benefit’ is shared (or allocated) between the two adjoining systems is an important and controversial issue in LCA and, to a large extent, depends on the goal and scope of the study being conducted.

[top]Steel and recycling

Steel is 100% recyclable and is highly recycled. In the UK, the overall average end-of-life recovery rate for steel from buildings has been estimated from surveys to be 96% It is important to remember that this is true or closed-loop recycling; every tonne of scrap recovered substitutes one tonne of primary steelmaking and this can happen again and again, with existing technology and without any degradation in terms of properties or performance of the steel.

[top]Steel production

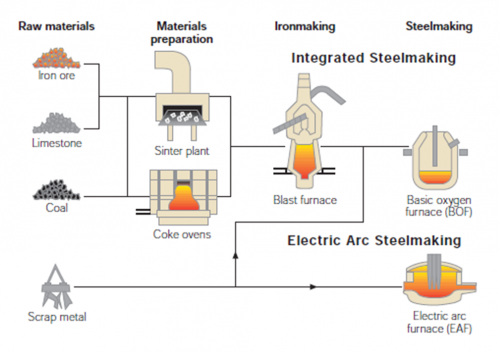

Steel is produced by one of two production routes:

- The primary or basic oxygen steelmaking (BOS) route; based primarily on the reduction of iron ore and incorporating typically 10% to 15% of scrap steel

- The secondary or electric arc furnace (EAF) route; 100% scrap based production.

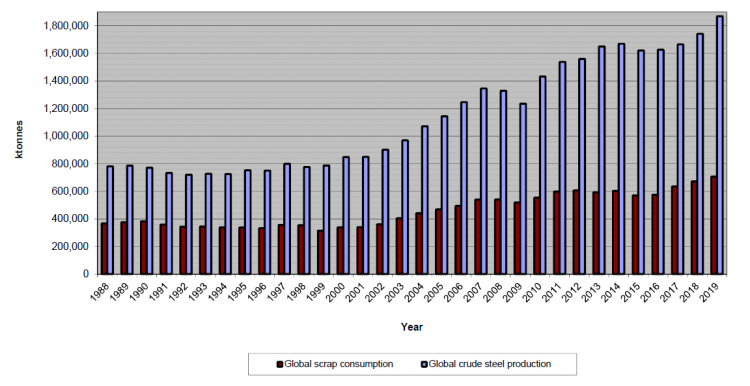

In 2019, global production of crude steel was 1.87 billion tonnes and the production split between these two routes was approximately 70:30 (BOS:EAF). Over 600 million tonnes (32%) of this total is estimated to have come from scrap. Although the amount of scrap recycled is generally increasing, scrap supply is constrained by availability and as shown, supply cannot currently meet the global demand for new steel and therefore primary steelmaking from iron ore is still required. It is noted that the greatest demand is in the developing economies where steel is being used to develop infrastructures and buildings. In many developed economies, including the UK, there is a much closer match between steel demand and scrap supply.

As shown in the figure below, steel scrap from both (primary and secondary) production routes is recycled back into either route. Therefore, although there are two distinct separate manufacturing routes, they are linked by the flow of steel scrap and therefore can be considered as a single system.

[top]Steel recycling

Since steel was first mass produced in the 1880s it has always been highly recycled. Principally because:

- Steel has a relatively high economic value - the price paid for UK scrap structural steel (grade OA) in January 2021 was £230 to £240 per tonne

- The versatility of steel means that it can be easily recycled or remanufactured into new applications as demand dictates

- Steel’s magnetic properties mean that it can be efficiently segregated from mixed waste streams.

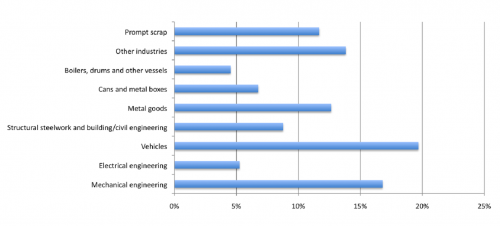

Steel is available in thousands of different compositions (grades), each tailored to specific applications in sectors as diverse as packaging, engineering, white goods, vehicles and construction. Construction is the largest market sector for steel in the UK accounting for around one third of steel consumption. This versatility promotes recycling since steel scrap can be blended, through the recycling process, to produce different types of steel (different grades and products) as demand dictates. For example, steel from redundant industrial machinery can be recycled into more contemporary products such as cars or white goods which, in turn, can be recycled into new, maybe as yet undiscovered, applications in the future. A case study on this involving the Teesside Meltshop at Lackenby can be accessed here.

Steel products in-use today all contain a proportion of recycled steel from previous incarnations. This can be one or many previous uses. Originally all ‘recycled’ steel was produced from iron ore and therefore how the initial impacts of primary production, are shared over subsequent uses of the same material is an important question in quantifying its whole life environmental impacts.

As long as recycling continues therefore, the life of a steel product is, in effect, infinite and individual incarnations or uses of a steel product, are merely parts of the larger life cycle of the material. By considering the environmental impact of these intermediate lifecycle stages in isolation, an incomplete, ‘snap-shot’ of the overall impact is obtained. For example, by only considering the recycling step but excluding the initial, generally larger, impact from the initial primary production.

This is a particular challenge in construction because of the incompatibility between different product life cycles and their scope of assessment. Steel (as a material) theoretically has an infinite life cycle, through multiple recycling stages, whereas building assessments are generally limited in scope, to the lifetime of the building; typically 60 years. This yields some methodological challenges on which there is a lack of consensus. The longer-term environmental benefits of highly recyclable materials like metals, is increasingly appreciated in the context of the circular economy and the benefits quantified by means of ‘whole life carbon assessment.’

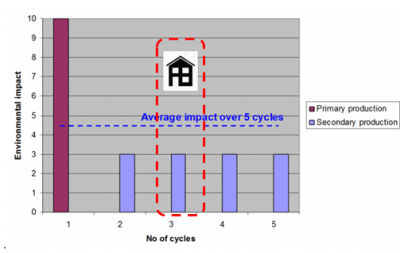

This is illustrated in the figure (right) which shows the environmental impact of a hypothetical metal product over five life cycles or five recycling steps. The environmental impact of the first or primary production process is 10 units and the impact of the secondary or subsequent process, i.e. the recycling process, is 3 units. A 100% recycling rate is assumed for simplicity. Note that for structural steel this is a realistic assumption see results from a recent survey.

If we take a ‘snap-shot’ of say the third life cycle, the environmental impact is 3 units. But this ignores the initial impact of the primary production step (Cycle 1). Similarly, if we only consider the first life cycle but ignore all subsequent cycles, the impact is 10 units. In reality, as shown, the average impact of the product is somewhere between the two; in this case, 4.4 units (10 + 4 x 3 = 22 divided by 5). This average value in practice will depend on the number of cycles and the recycling rate achieved for a particular product.

Although, in accordance with current LCA standards actual impacts have to be reported for each building life cycle, the longer term benefits of recycling metals should also be assessed and quantified as part of a whole life environmental impact assessment.

[top]Steel construction and recycling

Establishing accurate reuse and recycling rates for construction materials is difficult. (Recycling or reuse rate is defined as the proportion of material arising, from demolition, refurbishment, etc, that is recycled or reused).

Waste occurs during the construction and refurbishment of buildings and when they are ultimately demolished or deconstructed and therefore material becomes available for recycling at each of these stages. As prefabricated products and systems, waste from the manufacture of steel construction products is easily collected and segregated for recycling in the factory or fabrication workshop and, on the construction site, steel products generate very little or zero waste.

| Generic product | Wastage rates (%) | |

|---|---|---|

| Manufacture1 | Construction2 | |

| Sections | 4.1 | 0 |

| Profiled cladding and decking | 2.3 | 5 |

| Sandwich panels (steel only) | 3.9 | 5 |

| Composite floor decking | 1.4 | N/A |

| Light gauge steel | 3 | 2.5 |

1 Life cycle assessment (LCA) for steel construction, European Commission, EUR 20570 EN

2 Site wastage rates used for the Green Guide to Specification, BRE

While the amount of scrap steel that is collected for recycling is known, it is much more difficult to establish the amount of scrap steel arising from the construction and demolition of buildings. In the UK in 2018, 10mt of scrap steel were recovered (from all market sectors) for recycling. It is estimated that construction steel accounts for just 8% of this total. This proportion is much lower than 29% (which is the proportion of UK steel consumption used for construction) and reflects the longevity of steel construction products and implies that the stock of steel in UK buildings and infrastructure is increasing.

To establish recycling and reuse rates for steel construction products, a survey was carried out with demolition contractors in 2000. This survey was repeated in 2012[2]. The table gives the estimates for UK steel construction products resulting from the second of these surveys[2].

| Product | % Reused | % Recycled | % Lost |

|---|---|---|---|

| Heavy structural sections/tubes1 | 7 | 93 | 0 |

| Rebar (in concrete superstructures) | 0 | 98 | 2 |

| Rebar (in concrete sub-structure or foundations) | 2 | 95 | 2 |

| Steel piles (sheet and bearing) | 15 | 71 | 14 |

| Light structural steel | 5 | 93 | 2 |

| Profile steel cladding (roof/facade) | 10 | 89 | 1 |

| Internal light steel (e.g. plaster profiles, door frames) | 0 | 94 | 6 |

| Other (e.g. stainless steel) | 4 | 95 | 1 |

| Average (across all products) | 5 | 91 | 4 |

Summary of reuse and recycling rates from the 2012 Eurofer survey (with additional responses)[2].

1For practical purposes a 99% recycling/reuse rate is generally assumed to account for small losses of material during the lifecycle of the product.

[top]Reuse

As distinct from recycling, reuse of construction products involves their reuse with little or no reprocessing. Reuse offers even greater environmental advantage than recycling since there are no (or very few) environmental impacts associated reprocessing. For example, reusing a steel beam in its existing form is better than remelting it and rolling a new steel beam, i.e. the energy used to remelt and re-roll the beam is saved.

As with recycling, some construction products and systems are more amenable to reuse than others and therefore designers should be encouraged to think about not only how their buildings can be easily and effectively constructed but also how they can be efficiently deconstructed with a view to preserving the integrity of the reclaimed products for subsequent reuse. This is a new discipline for most designers.

Although complete buildings and different elements of steel buildings can be reused, here we focus on structural building elements.

Already some industries such as the agricultural sector (where aesthetics are generally of less concern than other sectors) commonly reuse steel structures and cladding components. In addition, salvage of construction materials has been undertaken for many years albeit it a relatively small and specialist scale. Common categories of salvaged construction products include:

- Architectural salvage

- Cobbles, slates, flagstones

- Bricks

- Reclaimed timber

- Reclaimed flooring

- Structural steel

- Steel portal frames

- Railway sleepers.

Sourcing reclaimed construction products has been enhanced via the use of the internet and the ability to easily search for specific products.

A case study showcasing the reuse of steel at the Honda central receiving building can be accessed here.

As an example of reuse in action, steel tubes recovered primarily from the oil and gas industry have been reused on a wide range of major construction projects, as illustrated in the video here. A report that quantifies the potential environmental benefits from reusing steel tubes is also available from Cleveland Steel and Tubes Ltd here.

[top]Barriers to reuse

There are many barriers to the more mainstream reuse of construction components within currently configured supply chains. These include:

Technical barriers:

- Lack of standardization of components

- Processing reclaimed sections through automated fabrication lines

- Ensuring and warranting the performance of reused components

- Lack of detailed knowledge of the product’s properties and in-use history (this may be important, for example, if the component has been subject to fatigue loading)

- Quality assurance of reused products

- Robustness of products in the deconstruction process, i.e. many lighter products do not survive the deconstruction process intact

- Practicalities of economic deconstruction including deconstructing composite components

Logistical barriers:

- Assured availability of supply

- Demolition programmes are often too short to enable contractors to deconstruct buildings

- Sufficient storage space for recovered products

- Deconstruction, as opposed to demolition using remote, high-reach equipment, has significant implications for the health and safety of workers

Cost:

- Lack of commercial drivers for reuse

- Cost of storage, cataloguing, refurbished products, etc.

- Cost of testing to verify and guarantee properties

- Client expectation that ‘second-hand’ products should be cheaper than new ones

- Additional cost of deconstruction over traditional demolition (which is generally quicker and less labour-intensive)

Liability:

- How to manage and apportion risk and liability associated with deconstruction and reuse.

[top]Reusing structural steel

Steel buildings and steel construction products are highly and intrinsically demountable. This potential is illustrated by the large number of temporary works systems that use steel components, e.g. scaffolding, formwork, sheet piles, etc. Provided that attention is paid to eventual deconstruction at the design stage, there is no technical reason why nearly all of the structural steel building stock should not be regarded as a vast ‘warehouse of parts’ for future use in new applications.

Steel can be reused at both the product and the building level. Already some industries, such as the agricultural sector, commonly reuse steel structures and cladding components.

Many steel construction products and components are highly re-usable including:

- Piles (sheet and bearing piles)

- Structural members including hollow sections

- Light gauge products such as purlins and rails.

The process is straightforward; for example, deconstructed sections are inspected to verify their dimensional properties; tested to confirm their mechanical properties and the section is then generally shot or sand blasted to remove any coatings and refabricated and primed to the requirements of the new project. This will usually involve cutting the ends of the beams and columns to the required length.

There is, however, significant scope for increasing reuse of steel construction products and work is underway within the sector to promote and facilitate this. The proportion of recovered products that are reused will increase as design for deconstruction is better understood and a stronger market for reusable steel construction products is stimulated. The ability of the steel construction sector to facilitate these advantageous processes has been enhanced by the standardisation of components and connections.

To help facilitate the reuse of existing structural steel, SCI has published a protocol (SCI P427) setting out recommendations for data collection, inspection and testing to ensure that reclaimed structural steelwork can be reused with confidence.

BCSA also published a Model specification is for the purchase of reclaimed steel sections in March 2022, to be used in conjunction with NSSS Annex J – Sustainability Specification. This model specification applies to the contract between the stockholder (the supplier) and the steelwork contractor (the purchaser) for steel products placed on the market as reclaimed structural steel sections for the fabrication of structural steelwork. It covers the selection and acceptance criteria for reclaimed steelwork, the technical specification for those steel products including tolerances on dimensions and shape and material performance requirements, product testing and quality management requirements and documentation.

At the building systems level, modular construction offer the greatest opportunities for reuse. Modules or pods can be deconstructed from the building and refurbished and reused on the same or an alternative building.

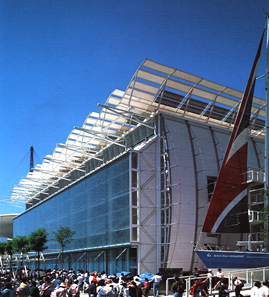

At a much larger scale, complete steel buildings can be reused. An early example is the British Pavilion at the Seville Expo in 1993 (see right). This innovative, energy efficient steel building was designed to be reused after the Expo.

Research carried out by the Steel Construction Institute[3] has estimated that there is around 100 million tonnes of steel in buildings and infrastructure in the UK. This ‘stock’ of steel is an important and valuable material reuse that will be reclaimed and either reused or recycled in the future.

Work is also underway to develop a national database of new structural steelwork so that all mechanical and chemical properties of the steel elements can be securely stored so that in the future, the provenance of the steelwork is known and it can be reused with confidence, without the need for testing and conservative reuse design assumptions.

[top]Design for reuse

To facilitate greater reuse it is important that designers not only use steel but also do what they can to optimise future reuse. Steps that the designer can take to maximise the opportunity for reusing structural steel include:

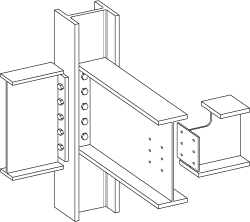

- Use bolted connections in preference to welded joints to allow the structure to be dismantled during deconstruction

- Use standard connection details including bolt sizes and the spacing of holes

- Ensure easy and permanent access to connections

- Where feasible, try to ensure that the steel is free from coatings or coverings that will prevent visual assessment of the condition of the steel.

- Minimise the use of fixings to structural steel elements that require welding, drilling holes, or fixing with Hilti nails; use clamped fittings where possible

- Identify the origin and properties of the component for example by bar-coding or e-tagging or stamping and keep an inventory of products

- Use long-span beams as they are more likely to allow flexibility of use and to be reusable by cutting the beam to a new length.

Work is also underway, led by SCI in the UK, to develop new structural steel systems that are easier to deconstruct so that the components can more easily be reused. In the context of multi-storey buildings, this has included:

- Opportunities for greater standardisation of structural grids to facilitate future reuse

- Optimised span:depth ratios for steel and composite beams

- Opportunities for greater standardisation and adjustment of connections to facilitate deconstruction

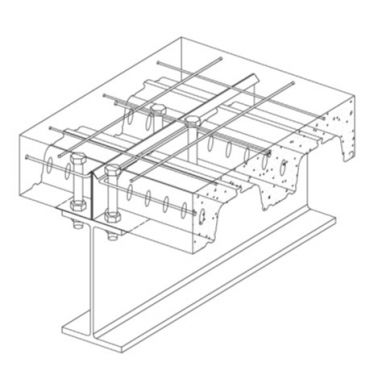

- Development and testing of new, demountable composite flooring systems

- Development and testing of adjustable and demountable connection systems

SCI has published (SCI P428) guidance on the design of composite beams using demountable shear connectors based on BS EN 1994-1-1[4]. The design methodology takes account of the different characteristics of the demountable shear connectors, in terms of their shear resistance, stiffness, and ductility. Design data on the performance of two types of demountable shear connector, using high-strength structural bolts and coupler systems, are presented.

- Demountable shear connectors with partial depth edge trim and U-bars

In the context of single storey, portal frame buildings, design for deconstruction and reuse research has included:

- Recommendations for standardised span increments and frame spacing

- Development of bolted haunch connection details

- Alternative column base connections which are accessible and demountable

In addition, the application of BIM to enable and facilitate future deconstruction and reuse has been explored.

[top]Reusing existing buildings

Existing buildings can be reused in-situ or dismantled and re-erected at a different location.

By reusing existing buildings, not only is demolition waste minimised but the new resources required to renovate and refurbish the building are much less than those required to construct a new building. In addition, reusing existing buildings can preserve the cultural and historic value of older buildings. Such as the redevelopment of Kinnaird House which achieved an excellent BREEAM rating.

- Kinnaird House, London, Architect: Trehearne Architects

Shallow floor system behind the retained facade

Modern renovation and refurbishment techniques and systems enable older buildings to be improved and brought up to today’s high standards of building performance in areas such as thermal and acoustic insulation.

[top]In-situ reuse

For many buildings it is the failure or deterioration of the envelope, rather than the structure, that precipitates its premature demolition. This can be aesthetic deterioration, changing fashion or, as is often the case, the need to update the envelope to modern standards of thermal performance.

A case study on reusing and extending buildings can be accessed here.

[top]Reuse at a new location

In the example shown, this steel car park in Munich, Germany was dismantled and re-erected at a new location.

A case study on relocating buildings, the Honda central receiving building, can be accessed here.

Another example of such a project is 9 Cambridge Avenue, a warehouse which was dismantled and re-built elsewhere on Slough Trading Estate to make way for the new Leigh Road bridge.

[top]References

- ↑ Re-use without melting: scrap re-use potential and emissions savings. Milford, R. 2010

- ↑ 2.0 2.1 2.2 Reuse and recycling rates of UK steel demolition arisings. Sansom, M and Avery, N. Proceedings of the ICE - Engineering Sustainability, Volume 167, Issue 3, 2014.

- ↑ Ley, J.: An environmental and material flow analysis of the UK steel construction sector, DEng thesis submitted to the University of Wales, 2003

- ↑ BS EN 1994-1-1: 2004 Eurocode 4. Design of composite steel and concrete structures. General rules and rules for buildings. BSI

[top]Further reading

- Sustainable materials - with both eyes open. J Allwood and J Cullen, Department of Engineering, University of Cambridge, UIT, 2012.

[top]Resources

- SCI P427 Structural Steel Reuse, Assessment, testing and design principles, 2019

- SCI P428 Guidance on Demountable Composite Construction Systems for UK Practice, 2020

- National Steelwork Specification for Building Construction, Annex J - Sustainability Specification, Publication No. 65/2022, BCSA, 2022

- Model Specification for the Purchase of Reclaimed Steel Sections, BCSA, 2022

[top]Case studies

[top]See also

- Steel manufacture

- Construction and demolition waste

- Life cycle assessment and embodied carbon

- The recycling and reuse survey

- Steel and the circular economy